PCBA Production Process

the Central Nervous System that Links Design with the Whole Device

With over 20 years of experience in PCBA manufacturing, our company provides professional, high-precision, and highly consistent PCBA solutions — from small-batch prototyping to large-scale mass production.

The Role of PCBA in the Electronics Manufacturing Process

The typical electronics manufacturing process is as follows:

Product Design → Engineering Verification (DFM/DFT) → Component Procurement → PCB Fabrication → PCBA Assembly → Testing & Verification (ICT/FCT) → Final Product Assembly → Quality Spot Check → Shipment

The PCBA assembly stage is the core link between ‘Engineering Verification’ and ‘Final Product Assembly,’ and it determines:

- Whether the circuit functions properly

- Whether the functional modules can operate in coordination

- Whether the subsequent final product assembly proceeds smoothly

- The stability and lifespan of the final product

PCBA Manufacturing Process

We offer full-process PCBA services, from single-layer and double-layer boards to multi-layer boards, mainly including the following steps:

1️⃣ SMT Assembly (Surface Mount Technology)

- Using fully automatic pick-and-place machines to accurately mount components such as resistors, capacitors, and IC chips onto the PCB surface.

- Employing reflow soldering to heat and weld the components, ensuring firm solder joints and reliable electrical connectivity.

- Inspection processes include SPI (Solder Paste Inspection), AOI (Automated Optical Inspection), and X-Ray solder joint inspection.

2️⃣ BGA Placement and Reflow Soldering

- BGA (Ball Grid Array) is a pinless package type that connects to the PCB only via an array of solder balls, suitable for high-density, high-performance chips such as MCUs, CPUs, and memory.

- We have professional BGA placement capabilities, paired with high-precision reflow ovens and temperature control systems to achieve reliable soldering.

- After BGA soldering, X-Ray inspection ensures all solder joints are uniform, with no open joints, bridges, or cold soldering.

- We also provide BGA rework and reballing services, significantly improving yield and repair capability.

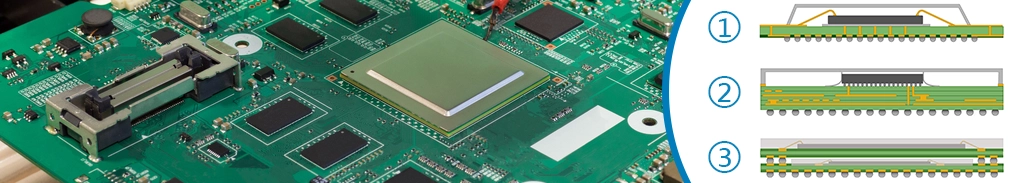

① Wire bonding to the BGA chip; ② Flip-chip bonding to the BGA chip; ③ BGA PoP packaging

① Wire bonding to the BGA chip; ② Flip-chip bonding to the BGA chip; ③ BGA PoP packaging

3️⃣ DIP Through-Hole Assembly

- Used for large-size or special components, employing wave soldering or manual soldering methods.

- Supports lean manufacturing techniques such as custom soldering fixtures and intelligent workstation management.

4️⃣ Post-Solder Cleaning and Surface Treatment

- Professional cleaning solutions are used to remove solder residues, ensuring insulation and reliability of the PCB.

- Optional coatings for moisture, corrosion, and mold protection are available, suitable for outdoor or high-humidity environments.

5️⃣ Electrical and Functional Testing (ICT / FCT)

- ICT (In-Circuit Test): Checks solder joint connectivity, component values, and electrical characteristics.

- FCT (Functional Circuit Test): Simulates real product operation to verify that the main control, interfaces, and communication modules function reliably.

- Custom test fixtures and automated test scripts can be provided according to the customer’s circuit requirements.

Why is PCBA the Key to Electronics Manufacturing?

✅ Core Functionality:

Almost all product functions are determined by the PCBA — it serves as the “electronic brain.”

✅ Technology-Intensive:

Requires high-precision equipment and experienced engineers; the technical barrier is high.

✅ Wide Impact:

The quality of the PCBA directly affects whether final assembly proceeds smoothly and whether the product operates reliably.

✅ Complex Testing:

Multiple levels of electrical, functional, and reliability tests are performed to ensure zero-defect delivery.

Our PCBA Manufacturing Capabilities

- SMT Production Lines: 27 high-precision SMT lines, capable of handling 01005 ultra-small components and

irregular-shaped parts. - Inspection Equipment: Automated systems for AOI, X-Ray, SPI, and ICT/FCT testing.

- Process Compatibility: Supports leaded/lead-free soldering, mixed assembly, double-sided SMT, and flexible

PCBs.

Quality System and Certification Support

- Quality Certifications: ISO9001 / ISO13485 / ISO14001

- Process Control: Full-process quality management including IQC, IPQC, FQC, and OQC

- Market Access Support: Assistance with product certifications such as RoHS, CE, FCC, REACH, etc.